Steam Boiler

Product Details:

- Color Silver

- Size Standard

- Condition New

- Product Type Steam Boiler

- Usage Industrial

- Voltage 220-440 Volt (v)

- Pressure High Pressure PSI

- Click to View more

Steam Boiler Price And Quantity

- 800000 INR/Number

- 01 Number

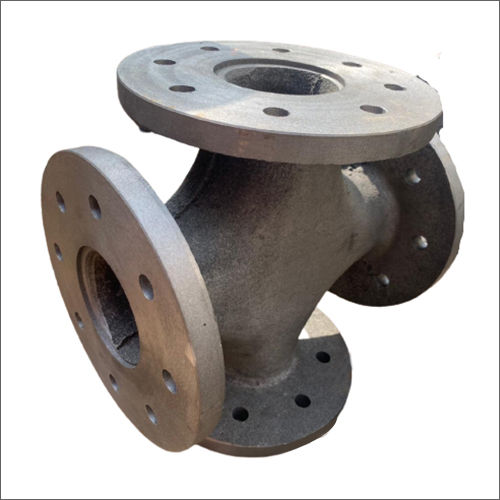

Steam Boiler Product Specifications

- Steam Boiler

- New

- Silver

- Standard

- High Pressure PSI

- Mild Steel

- 220-440 Volt (v)

- Industrial

Steam Boiler Trade Information

- 100 Number Per Month

- 10 Days

Product Description

Arrowcon energy Pvt Ltd steam boiler is a device used to create steam by heating water to generate energy or power. The steam produced is used for various purposes, including powering turbines for electricity generation, heating buildings, industrial processes, and more. Steam boilers are commonly used in power plants, factories, and other facilities.Here are the basic components and workings of a steam boiler:

-

Water Tank or Drum: This is where water is stored before being heated. The drum is a crucial component for separating steam from water.

-

Burner or Heating Element: The burner or heating element is responsible for heating the water in the boiler. It can use various fuels such as natural gas, oil, or electricity to generate the necessary heat.

-

Combustion Chamber: This is where the fuel is burned, producing hot gases that heat the water in the boiler.

-

Heat Exchanger: The heat exchanger is a system that transfers heat from the combustion gases to the water, raising its temperature and converting it into steam.

-

Steam Outlet: Once the water is heated, steam is produced and released through the steam outlet. This steam is then used for various applications.

-

Safety Valves: Steam boilers are equipped with safety valves to prevent excessive pressure buildup. These valves release steam if the pressure exceeds a safe level.

-

Pressure Gauge: This instrument measures the pressure inside the boiler, helping operators monitor and control the system.

-

Water Level Indicator: This device indicates the water level in the boiler. Maintaining the correct water level is crucial for safe and efficient operation.

-

Control System: Modern steam boilers often have sophisticated control systems that regulate fuel input, water flow, and other parameters to optimize efficiency and safety.

It's important to note that proper maintenance and adherence to safety guidelines are essential for the safe and efficient operation of steam boilers. Regular inspections, water treatment, and adherence to industry standards are critical to prevent accidents and ensure the longevity of the equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Components' category

|

ARROWCON ENERGY PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry